Temperature test standard

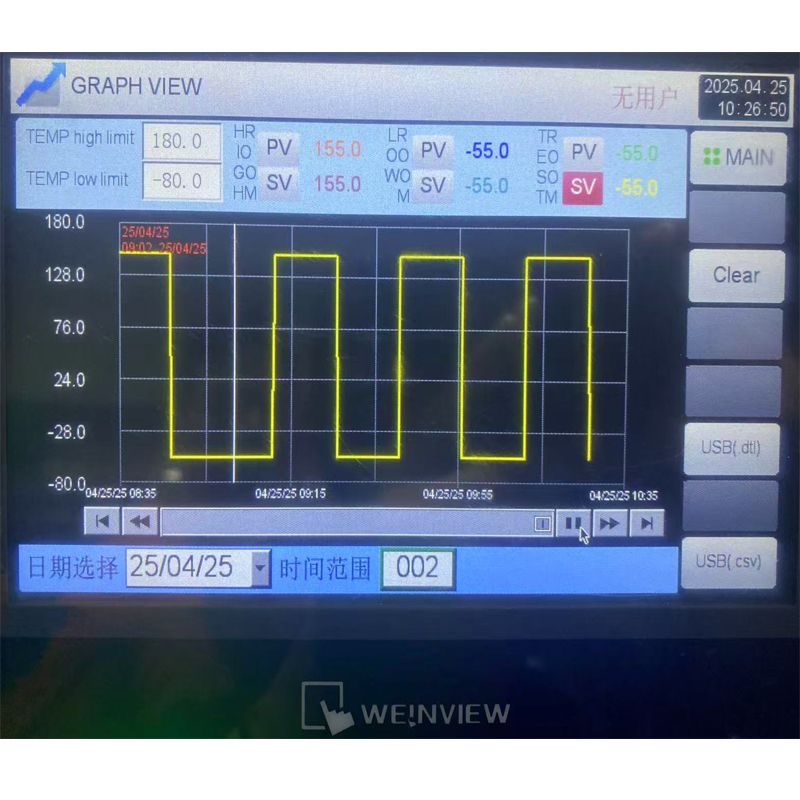

1. Temoerature Thermal Shock Test Chamber:

LED temperature shock tests have various combinations of shock temperatures, negative return times and cycle times, and can be conducted using either gas or liquid shock methods

-20℃(5min) 2min 90℃(5min) 2 gas thermal shock test

-30℃(5min) 5min 105℃(5min) 10 gas thermal shock test

-30℃(30min), 105℃(30min), 10 gas thermal shock test

at 100℃(30min) -40℃(30min) 100℃(15min) -40℃(15min) 5min 300 gas impact (high-brightness LED)

100℃(5min) -10℃(5min) 300 liquid impact (high-brightness LED)

| Temperature impact 1 | Negative regression time | Temperature impact 2 | cycle | Method of Impact | Marks |

|---|---|---|---|---|---|

| -20(5min) | 2min | 90(5min) | 2 | Gas Thermal Impact | - |

| -30(5min) | 5min | 105(5min) | 10 | Gas Thermal Impact | - |

| -30(30min) | - | 105(30min) | 10 | Gas Thermal Impact | - |

| 88(20min) | - | -44(20min) | 10 | Gas Thermal Impact | - |

| 100(30min) | - | -40(30min) | 30 | Gas Thermal Impact | - |

| 100(15min) | 5min | -40(15min) | 300 | Gas Thermal Impact | - |

| 100(5min) | - | -10(5min) | 300 | Luid Thermal Impact | High lighting-LED |

Refer to MIL-STD-883 Method 1010:

-55 ℃←→100℃, 15-minute residence, air-air storage,

5 minutes 50/100/1000;

-40 ℃ to 100℃, 15-minute retention,

air-air storage, 5 minutes 5/65/100/200;

-40 ℃ to 100℃, 15-minute retention, 10-second conversion, air-air storage, 15-minute 5/50/100

2. High-temperature and high-humidity test chamber

Temperature and humidity conditions and time:

40℃/95%R.H. 96 hours;

Life test at 60℃/85%R.H. 500 hours;

Life test at 60℃/90%R.H. 1000 hours; 85℃/85%R.H. 50 hours;

Life test at 85℃/85%R.H. 1000 hours

3. Life test-high low temperature test chamber :

Room temperature life test

Continuous lighting at 27℃ for 1000 hours with current;

High-temperature life test

Continuous lighting at 85℃ for 1000 hours with current;

Low-temperature life test

It can be continuously lit up at -40 ℃ for 1000 hours with current, and at -45 ℃ for 1000 hours with current

Heating test :

It should be carried out in accordance with the IEC60598 standard, and at the same time, refer to the LM80 report and specification sheet of the components. The specific standards are as follows:

IEC/ EN60598-1, GB7000.1 "Luminaires - Part 1: General requirements and tests";

IEC/EN 60598-2-1, GB7000.201 "Luminaires - Part 2-1: Particular requirements - Fixed general luminaires"

IEC/ EN60598-2-2, GB7000.202 "Luminaires - Part 2-2: Recessed luminaires with particular requirements"

IEC/EN 60598-2-3, GB7000.203 "Luminaires - Part 2-3: Luminaires for road and street lighting with particular requirements"

IEC/EN 60598-2-4, GB7000.204 "Luminaires - Part 2-4: Special requirements - Portable general luminaires"

IEC/EN 60598-2-5, GB7000.7 "Luminaires - Part 2-5: Special Requirements for Floodlighting fixtures"

IEC/EN62560, GB24906 "Safety Requirements for Self-Ballasted LED Lamps Above 50V for General Lighting"

IEC/EN62031, GB24819 "Safety Requirements for LED Modules for General Lighting"

IEC/EN 61347-1, GB19510.1 "Control devices for Lamps - Part 1: General provisions and Safety requirements" GB19510.12,

IEC/ EN61347-2-11 "Control devices for lamps - Part 2-11: Particular requirements for miscellaneous electronic circuits used in conjunction with lamps"

IEC/EN 61347-2-13, GB19510.14 "Control devices for lamps - Part 2-13: DC or AC electronic control devices for LED modules"

4. Humidity test standard

The humidity test mainly combines temperature for high-temperature and high-humidity experiments.

The temperature, humidity conditions and time are as follows:

40℃/95%R.H. 96 hours;

Life test at 60℃/85%R.H. 500 hours;

Life test at 60℃/90%R.H. 1000 hours;

85℃/85%R.H. 50 hours;

Life test at 85℃/85%R.H. 1000 hours

5. Temperature Cycle Test

Five types of LED lamps were placed in the test chamber with adjustable temperature change rate.

The temperature change range was set from -10℃ to 50℃.

The temperature change rate was greater than 1℃/min but less than 5℃/min.

The test chamber was maintained at high temperature and low temperature for 0.5 hours each, and the cycle was repeated 8 times.

The test requirements stipulate that after the temperature cycle test, the lamps must not experience electrical abnormalities such as leakage or failure to light up.

6. Constant damp heat test

Five types of LED lamps were placed in a constant temperature and humidity chamber with a relative humidity of 95% and a temperature of 45℃.

The power was connected and the lamps were lit for 48 hours according to the rated input voltage of the lamps.

The samples were taken out, the surface water droplets were wiped dry, and then they were placed under normal atmospheric pressure and room temperature to recover for 2 hours before being inspected.

The appearance should be free from rust, cracks or other mechanical damage.

The lamps should not have electrical abnormalities such as leakage of electricity or failure to light up

7.Vibration test standard

The reference standard is GB/T 33721-2017 "Test Methods for Reliability of LED Lamps", which is specifically divided into the following two categories:

8.Outdoor pole-mounted lamps

Vibration severity selection: Based on the application scope and materials of the product, select a severity level of 1.5G (Table 6) or 3G vibration (Table 7).

Test procedure:

Resonant frequency search: Within the frequency range of 2 to 30Hz, with an acceleration of 0.2g and a sweep rate of 1oct/min, search for the resonant frequency points of the lamp in the three axes (X/Y/Z) (if there are no resonant frequency points, select 30Hz for the resonant durability test).

Durability test: Conduct 10,000 fixed-frequency durability tests at the resonant frequency point of each axis, totaling 100,000 times. The test frequency is the resonant frequency measured in step one. If there is no resonant frequency, it is conducted at 30Hz. The acceleration is 1.5G or 3G; The test time is T = N/60f (N is the number of tests and f is the test frequency). The number of test samples can be one sample tested on all three axes or three samples, with each sample corresponding to one axis of testing

Upgrade Lab Authority now!

The LED TEST standard you just read, each set of data is precisely simulated by the TEST EQ constant temperature and humidity test chamber.

To reproduce top-level certification results, equipment stability determines success or failure --

✔ Reject comparison deviation | ✔ Eliminate temperature and humidity fluctuation | ✔ Guarantee zero test failure

⏰ Limited-time inquiry privilege: Customers who submit their requirements today will receive an additional "International Calibration White Paper for Testing Environment"

+ Priority capacity quotas!

Unlock Device Plan Now →