5.2 Chamber for exposure to moisture

The chamber for the exposure to moisture shall be so constructed that:

a) the temperature can be varied between 25 °C±2 K and 65 °C±2 K in a period of between 1,5 h and 2,5 h for both rising and falling temperatures;

b) the relative humidity can be maintained at (933) % during the periods of constant or rising temperature and between 80 % and 96 % during the falling temperature periods;

c) the conditions prevailing at any point in the working space are uniform and are as similar as possible to those prevailing in the immediate vicinity of suitably located temperature- and humidity-sensing devices; The air in the chamber shall therefore be continuously stirred at a rate necessary to maintain the specified conditions of temperature and humidity.

d) the specimens under test shall not be subj

ected to radiant heat from the chamber conditioning processes;

e) the water used for the chamber humidity system shall comply with the limits given in IEC 60068-2-67;

f) condensed water shall be continuously drained from the chamber and not used again unless it has been re-purified.

Precautions shall be taken to ensure that no

condensed water from the walls and roof of the test chamber can fall on the specimens.

5.3 Chamber for exposure to cold

The chamber for exposure to cold shall be so constructed that

a) the temperature can be maintained at-10°C ±2 K,

b) the conditions prevailing at any point in the working space are uniform and are as similar as possible to those prevailing in the immediate vicinity of suitably located temperature-sensing devices.

The air in the chamber shall therefore be continuously moving.

Care should be taken that the thermal capacity of the specimen under test does not appreciably influence conditions within the chamber.

The humidity chamber may be used for exposure to cold, in which case it shall meet the requirements of 4.1 and, in addition, shall be so constructed that

1) the temperature can be lowered from 25 °C ± 2 K to -10 °C ± 2 K in a period of not more than 30 min,

2) the specimen can be held at a temperature of -10 °C ± 2 K for a period of 3 h,

3) the temperature can be raised from-10 °C ±2 K to 25 °C±2 Kin a period of not more than 90 min.

6 Severities

The number of 24 h cycles shall be 10, unless otherwise specified. If other than 10, the relevant specification shall define the number.

7 Testing procedure

7.1 Preconditioning

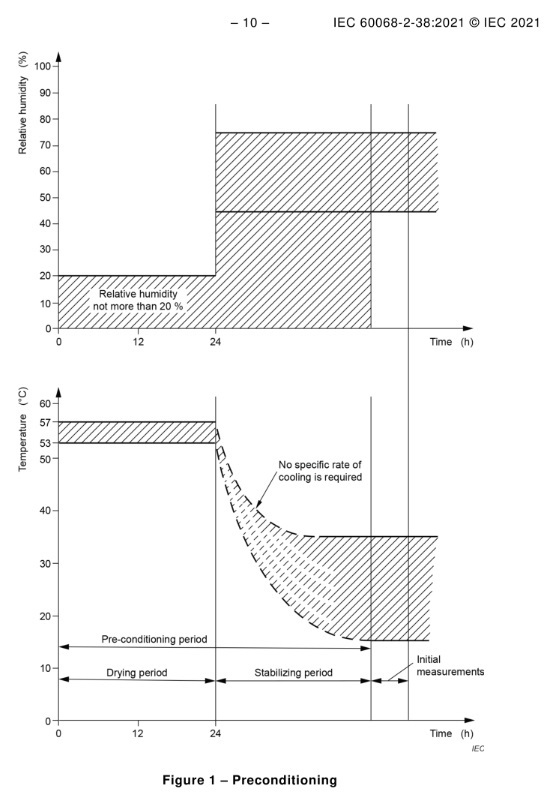

Unless otherwise specified, the specimens in the unpacked, switched-off, ready-for-use state shall be subjected to the conditions for "assisted drying" specified in IEC 60068-1 (55 °C ± 2 K with a relative humidity not exceeding 20 %) for a period of 24 h prior to the first cycle of the damp heat test.

The specimens shall then be allowed to attain thermal stability at standard atmospheric conditions for testing or, as otherwise specified, before the initial measurements are made.

Figure 1 gives an overview about the preconditioning phase. During the stabilizing period no specific rate of cooling is specified, however it shall not exceed 1 K/min.

7.2 Initial measurements

The specimens shall be visually inspected and electrically and mechanically checked as required by the relevant specification.

7.3 Conditioning

The total temperature tolerance of ±2 K given in this document is intended to take account of absolute errors in the measurement, slow changes of temperature and temperature variations of the working space.

NOTE This tolerance is valid for an empty test space during stabilized temperature/humidity conditions of the test. In some conditions, where the specimen has a negligible impact on the chamber control, the tolerances can still be valid for the chamber with specimen(s).

However, in order to maintain the relative humidity within the required tolerances, it is necessary to keep the temperature difference between any two points in the working space at any moment within narrower limits. The required humidity conditions will not be achieved if such temperature differences exceed 1 K. It may also be necessary to keep short-term fluctuations within these limits to maintain the required humidity.

The specimens shall be introduced into the humidity chamber, in the unpacked, switched-off, ready-for-use state, and mounted in the normal orientation, if this is known, or as otherwise specified and shall be subjected to 10 temperature/humidity cycles, each of 24 h duration.

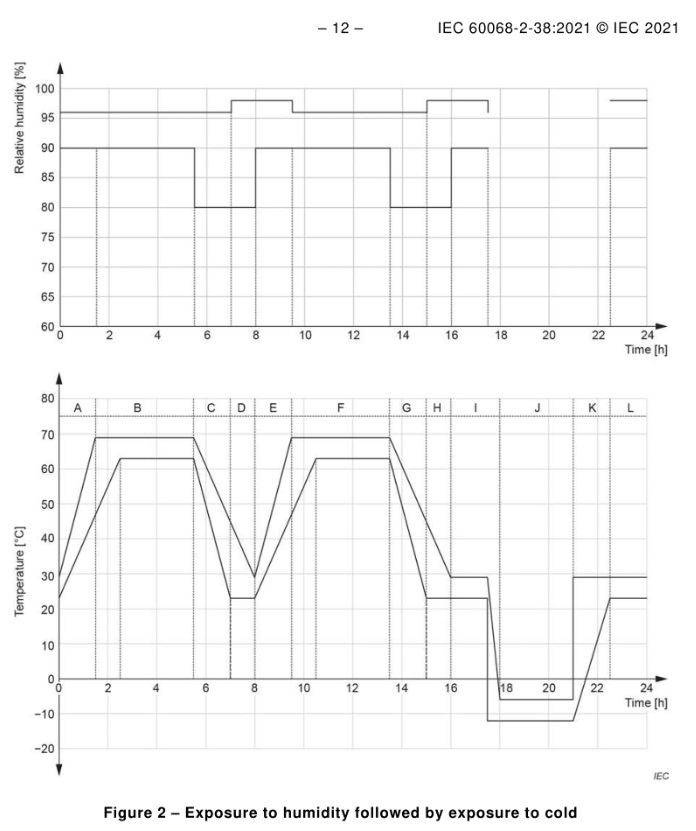

During any five of the first nine of the above cycles after exposure to the humidity subcycle (areas A to H in Figure 2), the specimens shall be subjected to cold. The position of the cold subcycles should be defined in the relevant specification.

This exposure may be performed either in the same chamber or in separate chambers. If separate chambers are used for the high-temperature/high-humidity and low-temperature subcycles of the test, the specimens should not be subjected to thermal shock conditions unless it is known that they are insensitive to this degree of thermal shock.

If a batch of specimens is subjected to thermal shock using the two chamber method and significant failures occur, a further batch shall be retested with gradual change of temperatures and shall be considered to have passed the test successfully if no significant failures occur under these conditions.

The remaining four of the first nine cvcles shall be run without exposure to cold (see 7.4.3 and Figure 3). The humidity cycles specified are the same in all cases.

7.4 Test cycle

7.4.1 Description of temperature/humidity subcycle

The description of the temperature/humidity subcycles is applicable to all cycles (see Figure 2 and Figure 3).

NOTE 1 The dotted lines in Figure 2 and Figure 3 are for orientation purposes only, aiming to give a better understanding of the test cycle. They place no indication for the order of the set points for the test.

At "zero time" of every 24 h cycle, the chamber condition shall be controlled to a temperature of 25 °C ± 2 K and relative humidity at 93(+/-3) %.

A The temperature of the chamber shall be continuously raised to 65 C ± 2 K in a period of between 1,5 h and 2,5 h. During this period, the relative humidity shall remain within the limits of 93(+/-3) %.

B The temperature and relative humidity in the chamber shall be maintained at 65 °C 2 K and 93(+/-3) % respectively, until 5,5 h after the start of the cycle.

C The temperature shall then be allowed to fall to 25 °C ± 2 K in a period of between 1,5 hand 2,5 h. During this period, the relative humidity shall remain within the limits of 80 % to 96 %.

D Beginning 7 h after the start of the cycle, the relative humidity shall remain within the limits of 80 % to 98 %.

E Beginning 8 h after the start of the cycle, the temperature shall again be raised to 65 °C 2 K in a period of between 1,5 h and 2,5 h. During this period, the relative humidity shall be 93(+/-3) %.

F Beginning 9,5 h after the start of the cycle, the relative humidity shall remain within the limits of 93(+/-3)%. The temperature and relative humidity in the chamber shall be maintained at 65 °C ± 2 K 93 (+/-3) % respectively, until 13,5 h after the start of the cycle.

G The temperature shall then be allowed to fall to 25 °C ± 2 K in a period of between 1,5 hand 2,5 h. During this period, the relative humidity in the chamber shall remain within the limits of 80 % to 96 %.

H Beginning 15 h after the start of the cycle, the relative humidity shall remain within the limits of 80 % to 98 %.

I The chamber shall then continue to run at a stabilized temperature of 25 °C ± 2 K and relative humidity of93(+/-3) %.

7.4.2 Description of cold subcycle

This description is applicable to any five of the first nine cycles (see Figure 2).

I Following the completion of the temperature/humidity subcycle (areas A to H in Figure 2), the chamber is maintained at a temperature of 25°C ±2 K and a relative humidity of 93(+/-3) % for a period of at least 1 h but not more than 2 h.

K The specimen shall then be exposed to cold by lowering the temperature of the chamber or transferring to a second chamber.

If the specimen is transferred from one chamber to another, the transfer should be completed within a period of 5 min. Beginning 17,5 h after the start of the cycle, the ambient temperature of the chamber shall be reduced to -10°C ±2 K. This temperature shall be reached 18 h after the start of the cycle.

Beginning 18 h after the start of the cycle, the temperature shall be maintained at -10 °C ± 2 K for a period of 3 h.

No requirement for humidity is specified during the entire cold subcycle.

L Beginning 21 h after the start of the cycle, the temperature shall be raised to 25 °C± 2 K. This temperature shall be reached 22,5 h after the start of the cycle (see Figure 2). If the specimen is transferred from one chamber to another, the transfer shall be completed within a period of 10 min to 15 min.

M The temperature of the chamber shall be maintained at 25 °C ± 2 K until the 24 h cycle is completed. During this period, the relative humidity shall be93(+/-3) %.

7.4.3 Description of 24 h cycles with no exposure to cold

This description is applicable to the remaining four of the first nine cycles (Figure 3).

Cycles which do not include a cold subcycle following the humidity/temperature subcycle are the same as described in 7.4.1, from A to H.

I . Following the completion of the temperature/humidity subcycle (areas A to H in Figure 2), the chamber shall be maintained at a temperature of 25 C ±2 K and, beginning 16 h after the start of the cycle, the relative humidity shall be 93(+/-3)%.

J Beginning 17,5 h after the start of the cycle, the chamber shall then continue to run at a stabilized temperature of 25 °C± 2 K and the relative humidity shall be kept within the limits of 93(+/-3) % until the end of the 24 h cycle.

NOTE This description is valid for Figure 3 (exposure to humidity not followed by exposure to cold) only.

7.4.4 Description of final cycle

In the final cycle, following the completion of the temperature and humidity subcycle, the chamber is maintained at a temperature of 25 °C ± 2 K and relative humidity of 93(+/-3) % for a period of 3,5 h after which the final measurements are made.

7.4.5 Intermediate measurements

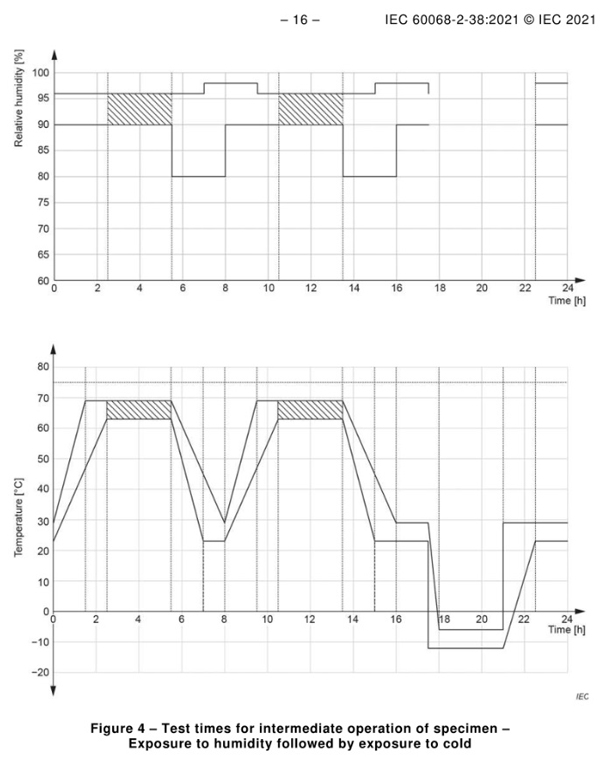

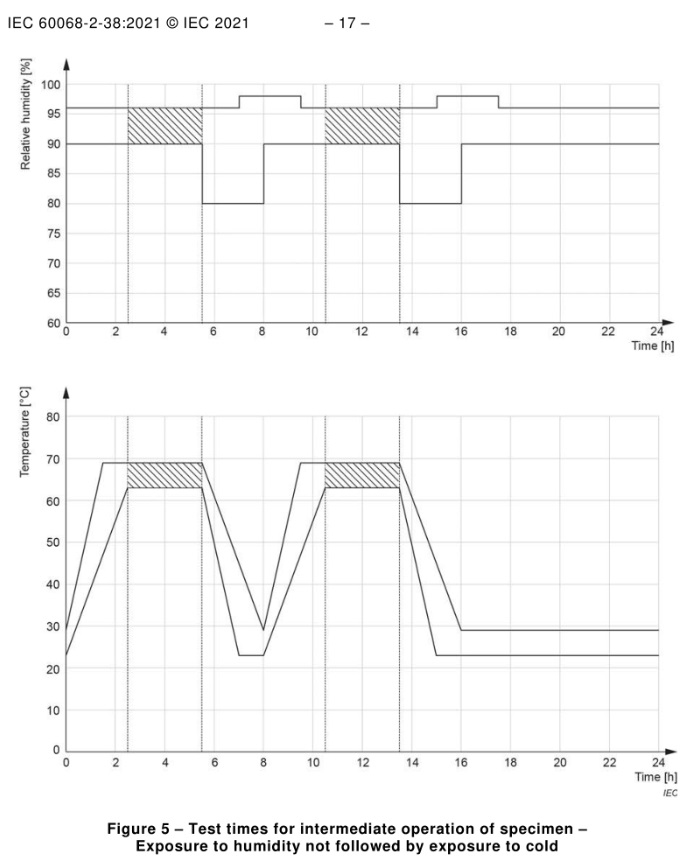

In order to carry out measurements on energized specimen, the following parts of the constant phases of the test cycles shown in Figure 2 and Figure 3 can be used:

- area beginning 2,5 h after the test has started until 5,5 h after the test has started (time indicated by end of area B in Figure 2 and Figure 3);

- area beginning 10,5 h after the test has started until 18 h after the test has started (time indicated by end of area F in Figure 2 and Figure 3)

During operation, functional checks only should be carried out, as permanent operation of thel specimen could interfere with the severity of the climatic stress applied to the specimen. Figure 4 and Figure 5 indicate the areas where these measurements can be carried out.

Accurate to IEC 68-2-38 standard, TEST EQ temperature and humidity chamber with ±0.1 ° C temperature control accuracy and long-term stability to help you pass strict tests! Click to inquire immediately to get a free technical solution and a limited-time quotation. Our professional technical team responds 24 hours a day to help you reduce costs and increase efficiency!