3.General description

This test comprises one or more temperature cycles in which the relative humidity is maintained at a high level.

Two variants of the cvcle are qiven which are identical except for the temperature fall period:l during this part of the cycle, variant 2 allows wider tolerances of relative humidity and the rate of temperature fall.

The upper temperature of the cycle and the number of cycles (see Clause 5) determine the test severity.

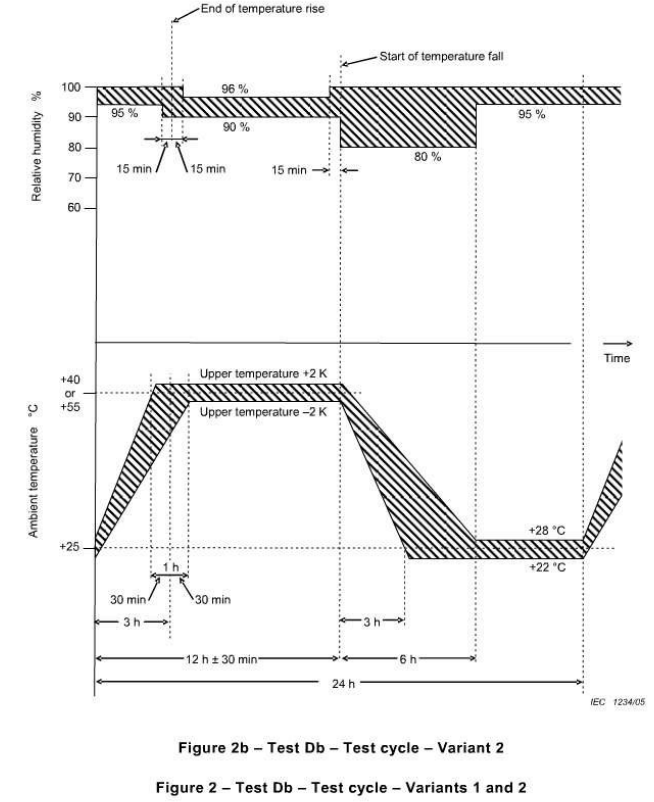

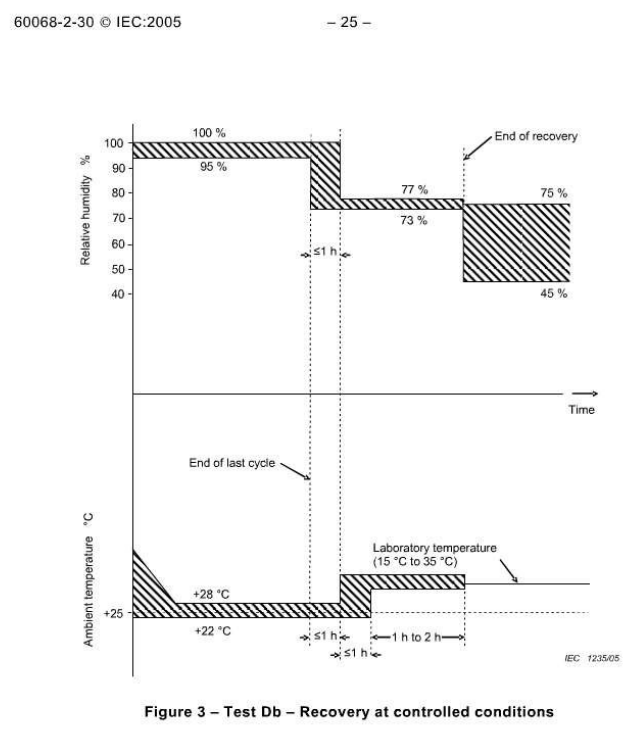

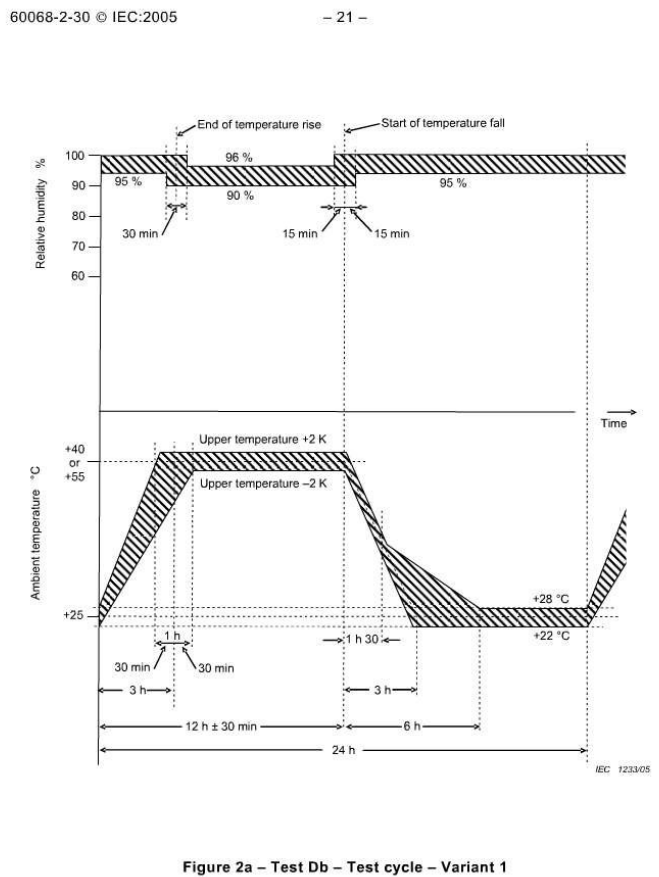

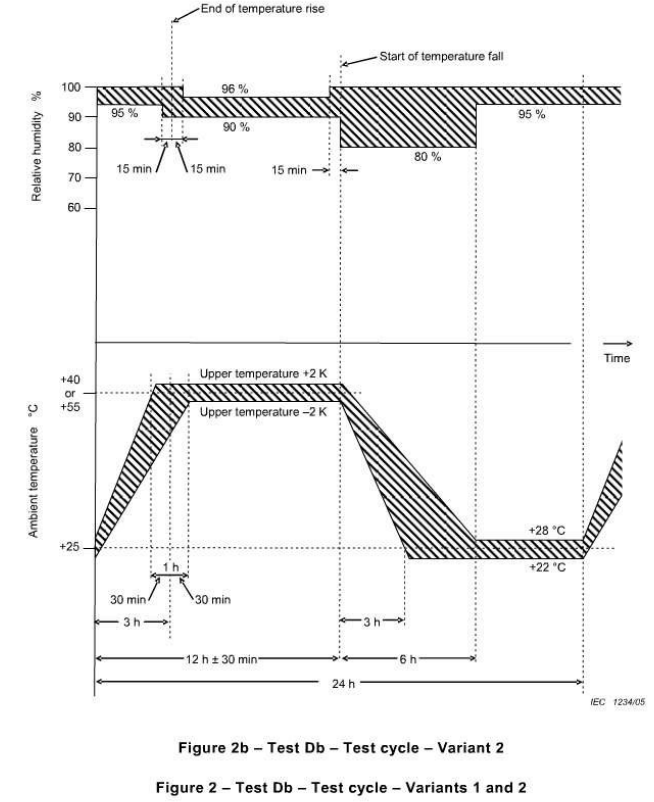

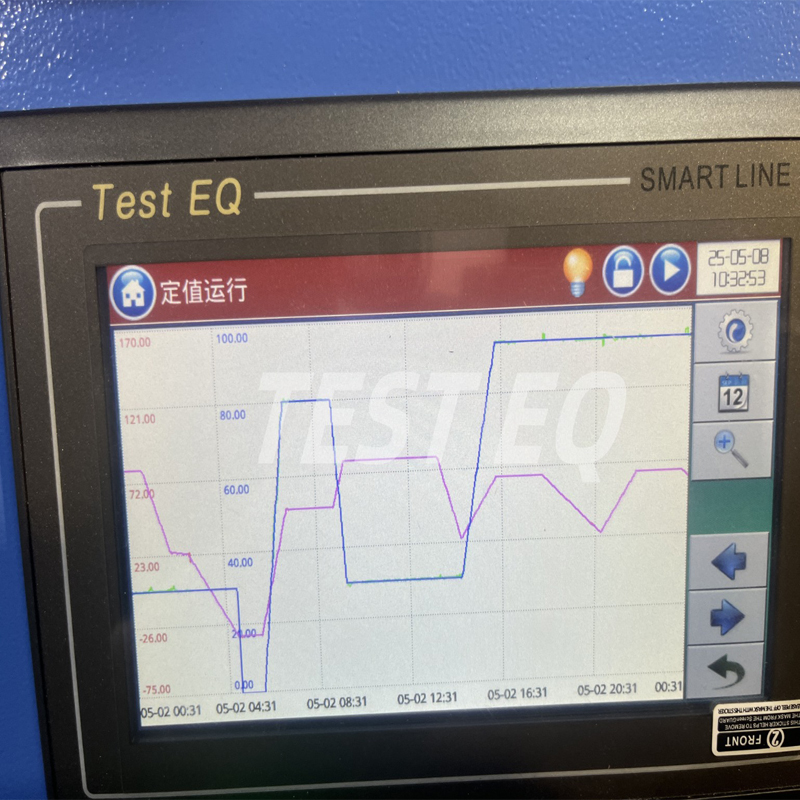

Test profiles illustrating the procedure are shown in Figures 1, 2a, 2b and 3.

4 Testing chamber-Construction requirements

4.1 The temperature can be varied cyclically between 25 C ± 3 K and the appropriate upper temperature specified with the tolerance and rate of change specified in 7.3 and Figures 2a or 2b as applicable.

The total temperature tolerance of t3 K is intended to take account of absolute errors in thel measurement, slow changes of temperature, and temperature variations of the working space.l

However, in order to maintain the relative humidity within the required tolerances, it is necessary to keep the temperature difference between any two points in the working space at any moment within narrower limits.

The required humidity conditions will not be achieved ifl such temperature differences exceed 1 K. It may also be necessary to keep short-term fluctuations within ± 0.5 K to maintain the required humidity.

4.2 The relative humidity in the working space can be maintained within the limits given in 7.3 and in Figures 2a or 2b as applicable.

4.3 Care shall be taken to ensure that conditions prevailing at any point in the working space are uniform and are as similar as possible to those prevailing in the immediate vicinity of suitably located temperature and humidity sensing devices.

The chamber shall meet the performance criteria as detailed in IEC 60068-3-6.

4.4 The Youdaoplaceholder0 under test shall not be subjected to radiant heat from the chamber conditioning processes.

4.5 Water used for the maintenance of chamber humidity shall have a resistivity of not less than 500 Ωm.

Condensed water shall be continuously drained from the chamber and not used again until it has been re-purified. Precautions shall be taken to ensure that no condensed water is allowed to fall on the specimens.

4.6 The dimensions properties and/or electrical loading of the specimens under test shall not appreciably influence conditions within the chamber.

5 Severities

5.1 The combination of the upper temperature and the number of cycles define the severity of the test.

5.2 The severity shall be chosen from the following:

a) upper temperature: 40 ° C,

number of cycles: 2, 6, 12, 21, 56;

b) upper temeprature :55℃

number of cycles:1,2,6.

7 Conditioning

The specimens shall be introduced into the chamber either in the unpacked, switched-off, ready-for-use state, or as otherwise specified in the relevant specification.

Where no specific mounting is prescribed, the thermal conduction of the mounting shall be low,

7.1 Temperature tolerances

The total temperature tolerance of ±2 K and ±3 K given in this standard is intended to take account of absolute errors in the measurement, slow changes of temperature, and temperature variations of the working space.

However, in order to maintain the relative humidity within the required tolerances, it is necessary to keep the temperature difference between any two points in the working space at any moment within narrower limits.

The required humidity conditions will not be achieved if such temperature differences exceed 1 K. It may also be necessary to keep short-term fluctuations within ± 0.5 K to maintain the required humidity.

7.2 Stabilizing period

The temperature of the specimens shall be stabilized at 25 C t 3 K (the definition of temperature stability is given in IEC 60068-1 and IEC 60068-5-2). This shall be achieved by either

a) placing the specimens in a separate chamber before introducing it into the test chamber, or,

b) adjusting the temperature of the test chamber to 25 C 3 K after the introduction of the specimens and maintaining them at this level until the specimens attain temperature stability.

During the stabilization of temperature by either method, the relative humidity shall be within the limits prescribed for standard atmospheric conditions for testing.

Following stabilization, with the specimens in the test chamber, the relative humidity shall be increased to not less than 95% RH at an ambient temperature of 25 °C± 3 K.

7.3 Description of the 24-hour cycle

7.3.1 The temperature of the chamber shall be raised to the appropriate upper temperature prescribed by the relevant specification.

The upper temperature shall be achieved in a period of 3 h ± 30 min and at a rate within the limits defined by the shaded areas in Figures 2a and 2b.

During this period, the relative humidity shall not be less than 95 % RH. During the last 15 min it shall not be less than 90% RH.

Condensation may occur on the specimen during this temperature-rise period.

NOTE The condensation condition implies that the surface temperature of the specimen is below the dew point of the air in the chamber.

7.3.2 The surface temperature of the specimen is below the dew point of the air in the chamber then be maintained within the prescribed limits for the upper temperature (±2 K) until 12 h ± 30 min from the start of the cycle.

During this period, the relative humidity shall be 93 % RH ± 3 %RH. During the first and last 15 min it shall be between 90 % RH and 100 % RH.

7.3.3 The temperature shall then be lowered in accordance with one of the two variants given below.

Variant 1 (see Figure 2a)

The temperature shall be lowered to 25 °C 3 K within 3 h to 6 h. The rate of fall for the first one and one half hours shall be such that, if maintained as indicated in Figure 2a, it wouldl result in a temperature of 25 °C ±3 K being attained in 3 h ± 15 min. The relative humidity shall be not less than 95 % RH. During the first 15 min it shall be not less than 90 % RH.

NOTE 1 See Annex A for descriptions of the type of specimen suitable for Variant 1.

Variant 2 (see Figure 2b)

The temperature shall be lowered to 25 C 3 K within 3 h to 6 h, but without the additional requirement for the first hour and one half as in variant 1. The relative humidity shall be not less than 80%R.H

NOTE 2 See Annex A for descriptions of the type of specimen suitable for Variant 2.

7.3.4 The temperature shall then be maintained at 25 C3 K with a relative humidity of not less than 95 % RH until the 24 h cycle is completed

.jpg)

.jpg)