RTCA DO-160 Temperature Altitude Testing Summary

Height test includes height test, pressure reduction test and overpressure test.

The altitude test had a maximum altitude of 70,00 feet, the decompression test simulated an emergency descent, and the overpressure test simulated a normal aircraft pressurization.

Temperature tests include operating low and high temperatures, ground survival temperatures, and simulations of short-time operating temperatures and in-flight cooling losses.

Practical temperature range limits include non-operating surface survival temperatures as low as -55 C and operating temperatures as high as 70 C.

RTCA DO-160G Altitude testing

The height test consists of three main tests.

Height testing is done by running the equipment at maximum duty cycle. Then, the pressure in the height test chamber is reduced. This test starts with the ambient temperature, which stabilizes as the pressure drops.

Decompression test is also done at ambient temperature. When the equipment is operating, the absolute pressure will move to an equivalent height of 8,000 feet.

The absolute pressure will then be reduced to the equivalent height of the maximum operating altitude of the aircraft on which the device will be installed.

Unless otherwise specified in the device specifications of the DO-160 test standard, the overvoltage test is performed when the device is not in operation.

The absolute pressure on the equipment is equivalent to an altitude of -15,000 feet.

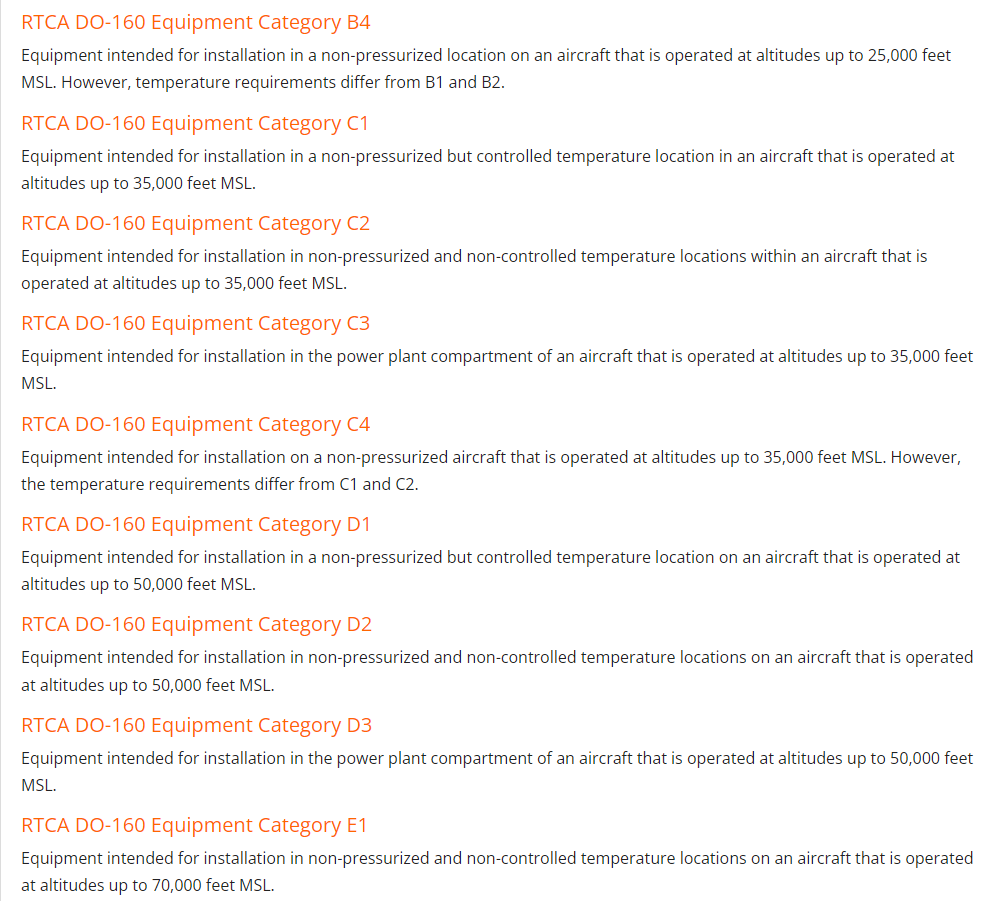

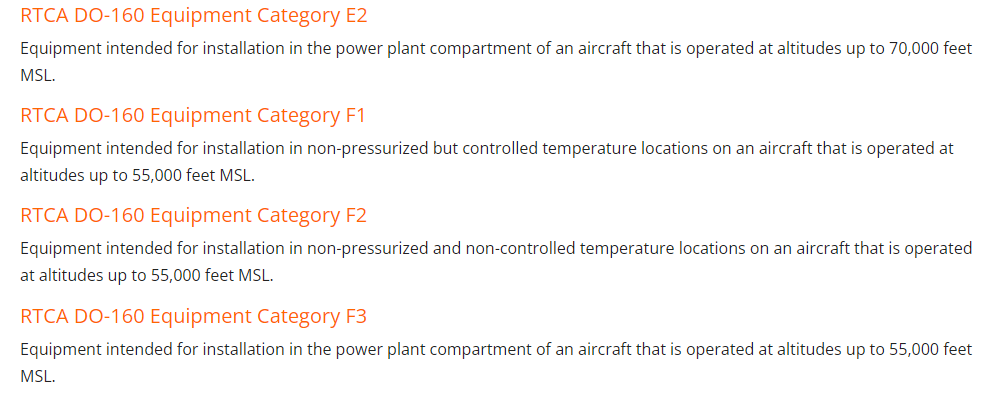

These tests determine the performance characteristics of the equipment for the applicable classes at the following temperatures and altitudes.

Temperature test

Temperature testing involves a variety of different tests. These temperature tests include the following:

Operating low temperature, that is, the lowest temperature at which equipment is usually exposed or needs to operate.

Operating high temperature, that is, the highest temperature at which the equipment is exposed in a specific installation area.

These areas include enclosed Spaces, behind dashboards, equipment racks, and power plant areas.

Short-time operating temperature, that is, the starting condition when the equipment is started after the ground immersion.

These temperature conditions are expected to occur infrequently and for short periods of time.

This is expected because cooling or heating air circulation or other methods of controlling temperature will be enabled at the same time as the equipment is operating.

Ground survival temperature, the minimum and maximum ground temperature to which equipment would normally be expected to be exposed during aircraft storage or exposure to extreme climates.

The equipment is not expected to operate within specification limits at these temperatures, but is not expected to be damaged.

Loss of cooling during flight,Indicates a failure of an external or internal system that normally provides dedicated cooling for the equipment.

Some equipment must be maintained for a limited time without cooling

Humidity testing

This test determines the ability of the equipment to withstand either natural or inducedhumid atmospheres.

The main adverse effects to be anticipated are: Corrosion. Change of equipment characteristics resulting from the absorption of humidity.

RTCA DO-160 section 6.0 classifies equipment in one of three categories; standard, severe and external.

The process of testing that an RTCA DO-160G test lab will follow will depend on the category.

However, in general, the process is a matter of first, exposing the device to a humid atmosphere.

A series of temperature and humidity changes will then occur over a specified period of time.

Upon completion of the humidity tests, electronic devices will be powered on. A functional check will be run.

For equipment that does not require electrical power, the device is exposed to temperature and a functional check is made.